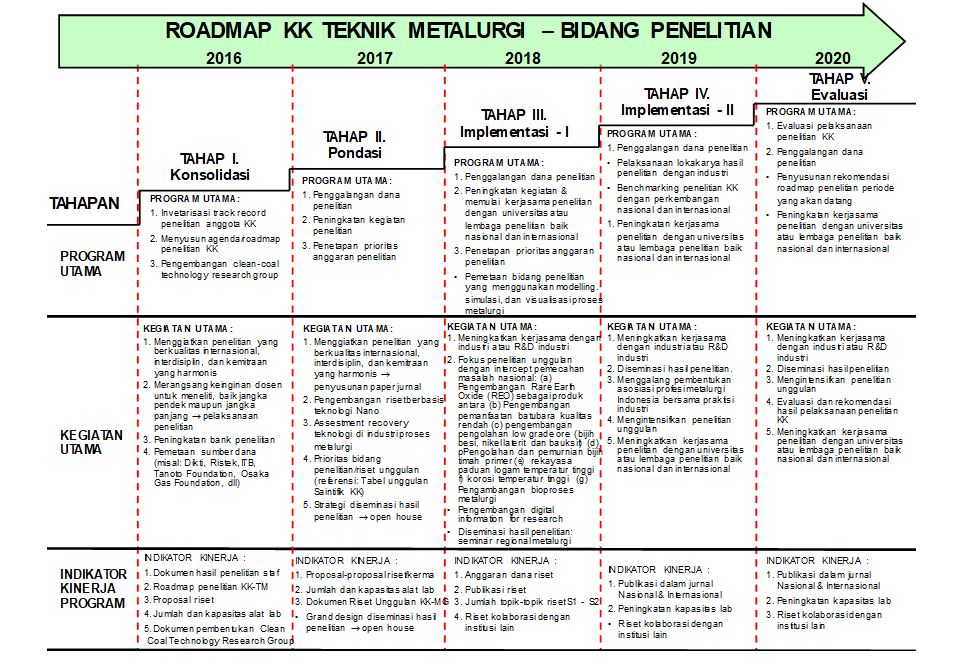

The applicable research scheme in the Metallurgical Engineering Group can be summarized in the following road map:

1. In the short term (1 year period: 2017):

- Continue laboratory-scale research in three sub-groups in the fields of mineral processing, metal extraction and its compounds and metal alloy engineering, with the target of reputable international scientific publications.

- Prepare plans and proposals for cooperation with industry to increase the scale of research from laboratory scale to pilot plant scale to produce prototypes that can be used as models for commercial products in the industry.

- Establish more concrete cooperation with user industries, especially related State-Owned Enterprises, such as PT Antam, PT Timah, PT Inalum, PT Krakatau Steel, PT Pindad, State Electricity Company (PLN), etc.

- Pursue funding and use of facilities for research from Kemenristekdikti, industry and ITB sources.

2. In the medium term (5-year period: 2017-2021):

- Continue laboratory-scale research in three sub-groups in the fields of mineral processing, extraction of metals and their compounds and metal alloy engineering for aspects that have not been revealed and improvement of results on previous research

- Product trial scale research (prototyping or pilot plant scale) resulting from collaboration with related industries.

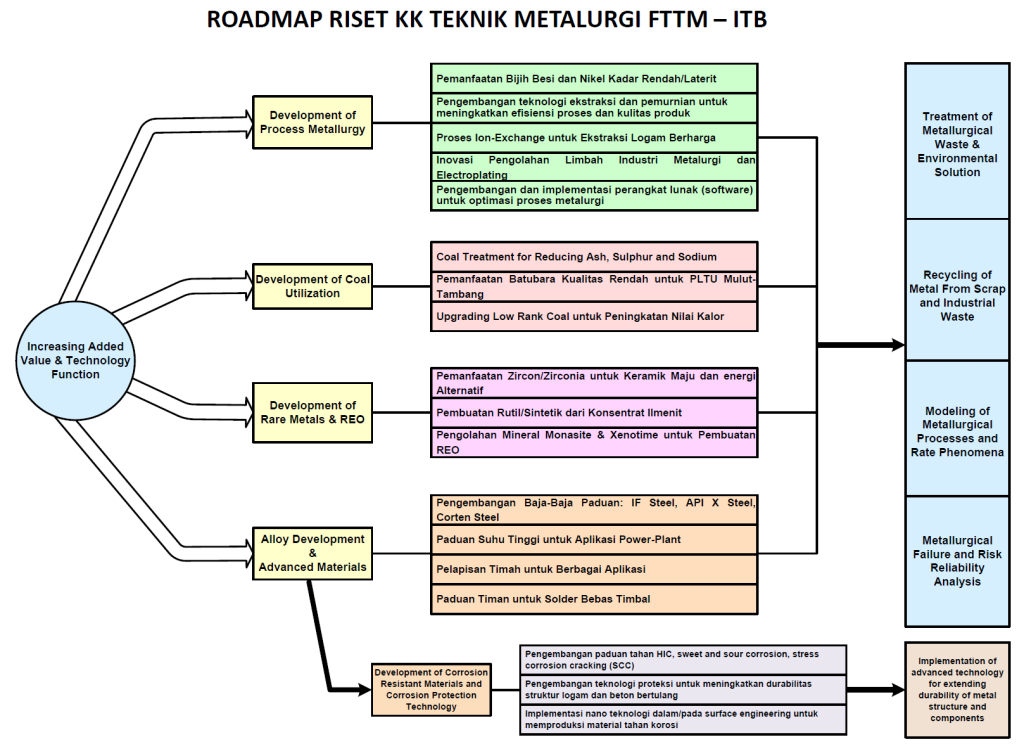

- In the field of mineral processing:

- Processing for the utilization of laterite ore (nickel, iron and bauxite).

- Graphite processing.

- Oil-shale processing.

- Development of bio-flotation technology.

- Up-grading and utilization of low rank coal.

- Processing and utilization of Indonesian coking coal (Indonesian coking coal)

- Processing of monazite and xenotime minerals for REO production.

- In the field of extraction of metals and their compounds (oxide systems):

- Utilization of low grade iron ore and nickel laterite.

- Development of extraction and purification technology to increase efficiency and product quality.

- Innovation in metallurgical industry waste processing and recycling.

- Development and implementation of software for metallurgical process optimization.

- The process of extracting and refining rare metals and rare earths.

- In the field of engineering of metal alloys and their compounds:

- Special steel (specialty steels).

- Development of metal alloys for high temperature components and energy savings.

- Metal alloys for medical needs.

- Corrosion control, development of protection and coating systems.

- Development of solid oxide electrolyte systems.

3. In the long term (period of more than 10 years):

Synergy is obtained for product development that is increasingly clear and profitable for both parties (ITB and industry in Indonesia).